A malfunctioning gas control valve in a Rheem water heater can be a homeowner’s nightmare, leading to inconsistent hot water, pilot light problems, or even a complete shutdown of the appliance. Understanding the potential causes and symptoms of a rheem water heater gas control or valve failure is crucial for timely diagnosis and repair. The intricacies of gas pressure, thermocouple functionality, and electronic ignition all play a role in the smooth operation of this critical component. Ignoring the early warning signs of a rheem water heater gas control or valve failure can ultimately lead to more extensive and costly repairs down the line, potentially shortening the lifespan of your water heater.

Understanding the Rheem Gas Control Valve

The gas control valve is the brain of your Rheem gas water heater. It’s responsible for regulating the flow of gas to the burner, ensuring safe and efficient operation. This intricate device monitors various safety parameters, including pilot light presence, gas pressure, and temperature, and shuts down the gas supply if any irregularities are detected.

Key Components of the Gas Control Valve:

- Thermocouple: Generates a small electrical current that keeps the pilot light valve open.

- Gas Pressure Regulator: Maintains a constant gas pressure to the burner.

- Solenoid Valves: Open and close to control the flow of gas.

- Temperature Sensor: Monitors the water temperature and adjusts the gas flow accordingly.

Common Causes of Gas Control Valve Failure

Several factors can contribute to a rheem water heater gas control or valve failure. Diagnosing the precise cause often requires a skilled technician, but understanding the potential culprits can help you communicate the issue effectively.

- Thermocouple Issues: A weak or faulty thermocouple can prevent the pilot light from staying lit.

- Sediment Buildup: Sediment in the water tank can clog the gas control valve and impair its function.

- Gas Pressure Fluctuations: Inconsistent gas pressure can damage the valve’s internal components.

- Electrical Problems: Issues with the igniter or wiring can prevent the valve from opening.

- Corrosion: Over time, corrosion can damage the valve’s internal mechanisms.

Troubleshooting and Potential Solutions

While some troubleshooting steps can be taken by homeowners, dealing with gas appliances requires extreme caution. If you are not comfortable working with gas lines or electrical components, it’s always best to consult a qualified technician.

Here’s a table comparing common symptoms and potential solutions:

| Symptom | Possible Cause | Possible Solution |

|---|---|---|

| Pilot light won’t stay lit | Faulty thermocouple | Replace the thermocouple |

| No hot water | Gas control valve failure | Replace the gas control valve (consult a technician) |

| Water heater makes unusual noises | Sediment buildup | Flush the water tank |

| Gas smell near the water heater | Gas leak | Evacuate the area and call the gas company immediately! |

Preventative Measures

Regular maintenance is key to preventing a rheem water heater gas control or valve failure. Flushing the water tank annually to remove sediment, inspecting the thermocouple for damage, and ensuring proper ventilation can all extend the lifespan of your water heater and reduce the risk of costly repairs.

Ultimately, addressing a rheem water heater gas control or valve failure requires careful assessment and potentially professional intervention. If you suspect an issue, don’t hesitate to contact a qualified technician to ensure the safety and efficiency of your water heating system.

ADVANCED DIAGNOSTICS AND REPAIR PROTOCOLS

A comprehensive diagnostic approach to a suspected gas control valve malfunction necessitates the utilization of calibrated testing equipment and adherence to established safety protocols. Prior to any intervention, the gas supply to the unit must be completely shut off, and appropriate lockout/tagout procedures implemented. Subsequent steps should involve a thorough visual inspection for signs of physical damage, corrosion, or gas leaks. A manometer should be employed to verify the incoming gas pressure adheres to the manufacturer’s specified range. Deviation from this range may indicate issues with the gas supply line or the upstream regulator, requiring separate remediation.

DETAILED TESTING PROCEDURES:

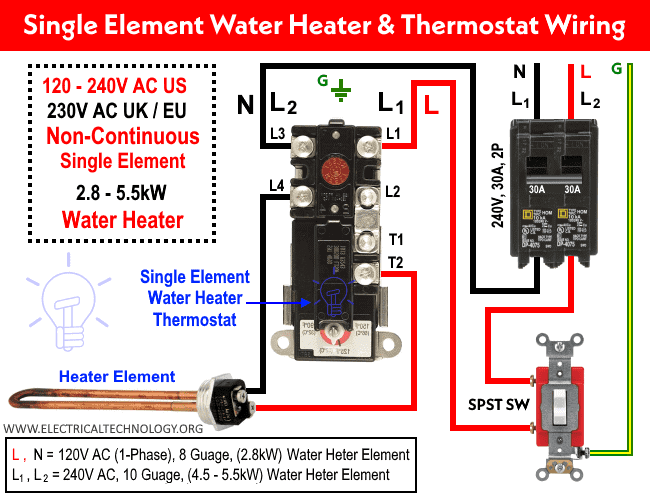

– Thermocouple Voltage Measurement: Employ a multimeter to measure the voltage generated by the thermocouple. An output below the manufacturer’s specified minimum indicates a failing thermocouple necessitating replacement.

– Gas Valve Continuity Testing: Use a multimeter to test the continuity of the gas valve solenoid coils. A lack of continuity signifies a faulty solenoid requiring valve replacement.

– Pilot Assembly Inspection: Examine the pilot assembly for obstructions or damage. Clean or replace as needed to ensure a stable pilot flame.

– Ignition System Verification: For units equipped with electronic ignition, verify the proper operation of the spark igniter. A weak or absent spark can prevent the pilot light from igniting.

CONSIDERATIONS FOR VALVE REPLACEMENT

In situations where the gas control valve is deemed irreparable, replacement is the only viable solution. It is paramount to procure an OEM (Original Equipment Manufacturer) replacement valve that is specifically designed for the Rheem water heater model in question. Using a non-OEM valve can compromise the unit’s performance, safety, and warranty coverage. The replacement procedure should be executed by a qualified technician adhering to the manufacturer’s instructions and all applicable safety codes. Following installation, a thorough leak test using a gas leak detection solution is mandatory to ensure the integrity of the gas connections.

LONG-TERM MAINTENANCE AND PERFORMANCE OPTIMIZATION

To ensure sustained performance and longevity of the Rheem gas water heater, a proactive maintenance regimen is highly recommended. This includes annual flushing of the tank to remove sediment accumulation, which can impede heat transfer and contribute to premature component failure. Regular inspection of the venting system is also crucial to ensure proper exhaust of combustion byproducts. Obstructions in the venting system can lead to carbon monoxide buildup, posing a serious health hazard. Periodic inspection and cleaning of the burner assembly are also advisable to maintain optimal combustion efficiency.

The continued safe and efficient operation of a Rheem gas water heater is contingent upon adherence to established maintenance protocols and prompt attention to any signs of malfunction. Consistent monitoring and preventative measures are essential for maximizing the lifespan of the appliance and minimizing the risk of unforeseen disruptions to hot water service.