Building a house is a monumental undertaking, requiring careful planning and a comprehensive understanding of the necessary materials. From the foundation to the roof, each component plays a crucial role in the structural integrity and longevity of the dwelling. A detailed list of construction materials needed to build a house is essential for accurate budgeting, efficient procurement, and ultimately, a successful construction project. Therefore, understanding the specifics of a list of construction materials needed to build a house is paramount for any aspiring homeowner or contractor.

Foundation Materials

The foundation is the bedrock of any home, providing stability and support. The materials used here must be incredibly durable and resistant to the elements.

- Concrete: Used for pouring the foundation slab or footings. The type of concrete will depend on soil conditions and building codes.

- Rebar (Reinforcing Steel): Embedded within the concrete to provide tensile strength and prevent cracking.

- Gravel: Used as a base layer for drainage and leveling beneath the concrete slab.

- Formwork: Temporary structures (usually wood or metal) used to contain the concrete while it cures.

- Waterproofing Membrane: Applied to the exterior of the foundation to prevent water intrusion.

Framing Materials

The framing forms the skeleton of the house, providing the structural support for walls, floors, and the roof.

- Lumber: Dimensional lumber (2x4s, 2x6s, etc.) is used for studs, joists, and rafters. Different grades of lumber are suitable for different applications.

- Engineered Wood Products: LVL (Laminated Veneer Lumber), PSL (Parallel Strand Lumber), and I-joists offer greater strength and stability compared to traditional lumber, especially for long spans.

- Sheathing: Plywood or OSB (Oriented Strand Board) is attached to the framing to provide rigidity and a nailing surface for siding and roofing.

- Fasteners: Nails, screws, and construction adhesives are used to connect framing members.

Exterior Materials

Exterior materials protect the house from the elements and contribute to its aesthetic appeal.

Roofing Materials

- Asphalt Shingles: A common and cost-effective roofing option.

- Metal Roofing: Durable and long-lasting, available in various styles and colors.

- Tile Roofing: Provides a classic and elegant look, but can be more expensive.

- Underlayment: A waterproof barrier installed beneath the roofing material to protect the sheathing.

Siding Materials

- Vinyl Siding: Low-maintenance and relatively inexpensive.

- Wood Siding: Offers a natural and attractive look, but requires regular painting or staining.

- Brick Veneer: Provides a durable and classic appearance.

- Stone Veneer: Adds a touch of elegance and sophistication.

Interior Materials

Interior materials create a comfortable and functional living space.

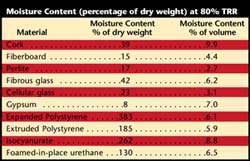

- Insulation: Fiberglass batts, spray foam, or cellulose insulation are used to regulate temperature and reduce energy costs.

- Drywall: Used to create smooth interior walls and ceilings.

- Flooring: Hardwood, tile, carpet, laminate, and vinyl are all popular flooring options.

- Paint: Used to add color and protect interior surfaces.

- Doors and Windows: Essential for security, ventilation, and natural light.

Plumbing, Electrical, and HVAC Materials

These systems are crucial for providing essential services to the home.

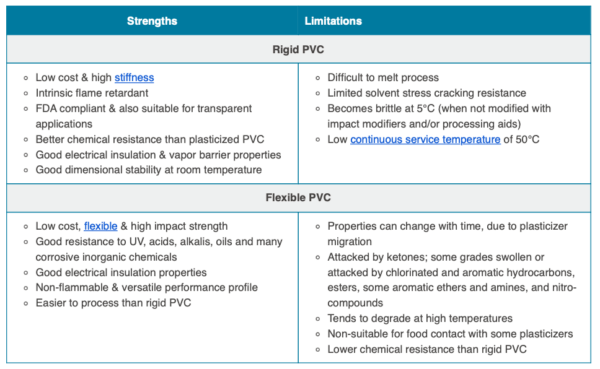

- Pipes and Fittings: Copper, PVC, or PEX pipes are used for water supply and drainage.

- Wiring and Electrical Components: Wires, outlets, switches, and circuit breakers are needed for the electrical system.

- HVAC Equipment: Furnace, air conditioner, and ductwork are needed for heating, ventilation, and air conditioning.

Creating a comprehensive list of construction materials needed to build a house can seem daunting, but it’s a vital step in ensuring a successful and cost-effective building project. Remember to consult with experienced contractors and suppliers to ensure you have a complete and accurate list tailored to your specific needs and building plans.

Beyond the fundamental categories, consider the smaller components often overlooked; These include sealants and caulking for weatherproofing, adhesives for various applications, and hardware such as nails, screws, bolts, and hinges. Don’t forget about landscaping materials such as topsoil, mulch, and plants if your project includes exterior improvements. Scaffolding and safety equipment are also crucial, though often rented rather than purchased.

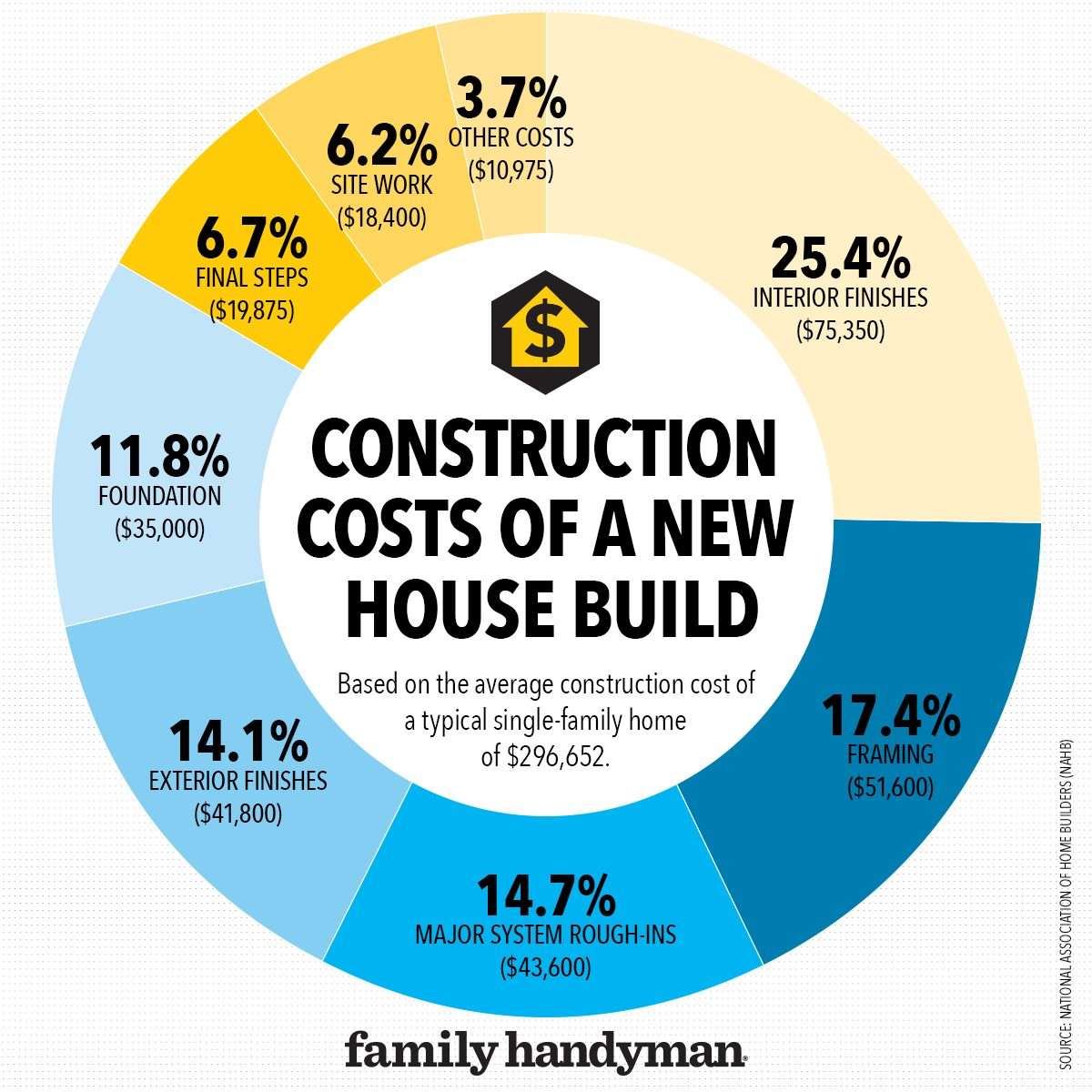

ESTIMATING MATERIAL QUANTITIES

Accurately estimating the quantity of each material required is essential for budgeting and avoiding shortages or overages. Several factors influence these estimates, including the size and complexity of the house, the chosen design, and any unique features. Consult with architects, engineers, and experienced contractors to obtain accurate quantity takeoffs. Software tools and online calculators can also assist in this process.

CONSIDER WASTE FACTORS

Always factor in waste when estimating material quantities. Some materials, such as lumber and flooring, are inevitably cut and trimmed, resulting in scrap. A general rule of thumb is to add a waste factor of 5-10% to most material estimates. For more complex projects or materials prone to breakage, a higher waste factor may be necessary.

SOURCING AND PROCUREMENT

Once you have a comprehensive list of materials and estimated quantities, the next step is to source and procure the necessary supplies. Explore different suppliers, including local lumberyards, home improvement stores, and online retailers. Obtain quotes from multiple suppliers to compare prices and terms.

FACTORS TO CONSIDER WHEN CHOOSING A SUPPLIER

– Price: Compare prices from different suppliers, but don’t solely focus on the lowest price.

– Quality: Ensure that the materials meet the required quality standards.

– Availability: Verify that the supplier can provide the materials when needed.

– Delivery: Inquire about delivery options and associated costs.

– Reputation: Check the supplier’s reputation and customer reviews.

MATERIAL STORAGE AND HANDLING

Proper storage and handling of construction materials are crucial to prevent damage, theft, and accidents. Designate a secure and organized storage area on the construction site. Protect materials from the elements, such as rain, snow, and sunlight. Follow manufacturer’s instructions for handling and storing specific materials.

The creation and execution of the list of construction materials needed to build a house is a multifaceted process that demands attention to detail, careful planning, and collaboration with experienced professionals. By following these guidelines, you can ensure a smooth and successful construction project.