The question of what is the absolute cheapest material to build a house with is complex and often depends heavily on location, availability, and labor costs. While there’s no single definitive answer, exploring various affordable options can shed light on how to minimize construction expenses. Ultimately, the “cheapest” material might not always be the most practical or long-lasting, so it’s crucial to consider factors beyond initial price. Understanding the pros and cons of each contender is essential for making an informed decision about the most cost-effective and suitable building material for your specific needs and circumstances. Let’s delve into some possibilities for the cheapest material to build a house with.

Exploring Affordable Building Materials

Several materials vie for the title of “cheapest,” each with its own unique set of advantages and disadvantages. Here are some contenders:

- Reclaimed Materials: Using salvaged wood, bricks, or even shipping containers can significantly reduce material costs. However, labor costs for cleaning, preparing, and integrating these materials might be higher.

- Earthbags/Sandbags: Filling bags with readily available soil offers a very low-cost option. This method is labor-intensive and requires specific building techniques to ensure structural integrity.

- Wood (Specifically, Lumber): In many regions, locally sourced lumber remains a relatively inexpensive option, especially for framing. However, lumber prices fluctuate and are subject to environmental factors and supply chain disruptions.

- Concrete Blocks (CMU): Concrete blocks offer a durable and relatively inexpensive building solution, especially in areas where they are readily available.

Factors Influencing Material Costs

The actual cost of any building material depends on several key factors:

- Location: Transportation costs can drastically increase the price of materials, making locally sourced options more appealing.

- Availability: The scarcity of a particular material will drive up its price.

- Labor Costs: Some materials are easier to work with than others, impacting labor expenses. Highly specialized skills can significantly increase the overall project cost.

- Building Codes and Permits: Certain materials might require more extensive (and expensive) modifications to comply with local regulations.

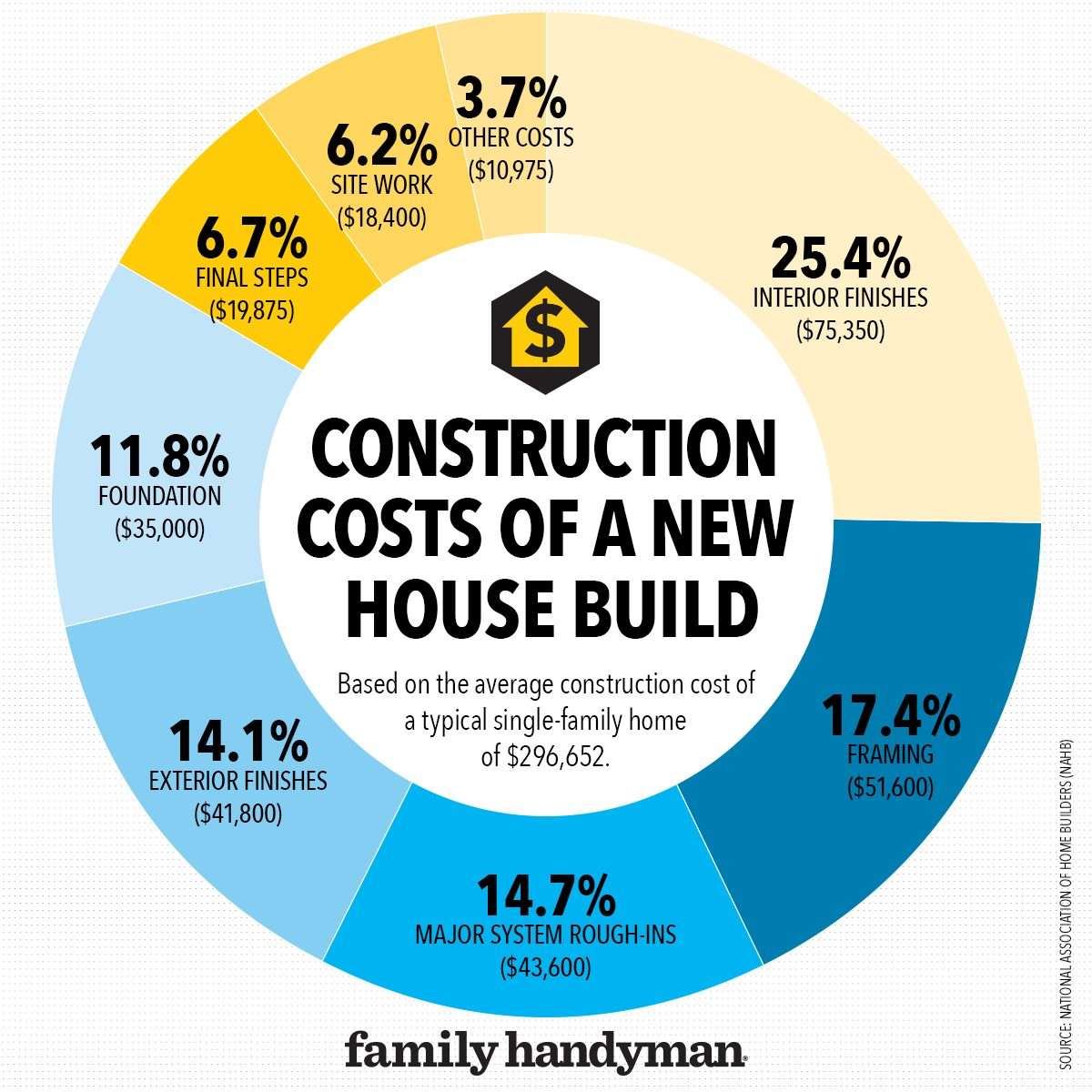

Comparison Table: Affordability vs. Other Factors

| Material | Approximate Cost (Relative) | Durability | Ease of Construction | Sustainability |

|---|---|---|---|---|

| Reclaimed Materials | Low (Variable) | Variable | Moderate to High | High |

| Earthbags/Sandbags | Very Low | Moderate | High | Moderate |

| Lumber | Low to Moderate | Moderate | Low to Moderate | Moderate (if sustainably sourced) |

| Concrete Blocks (CMU) | Low to Moderate | High | Low to Moderate | Low |

Ultimately, determining the absolute cheapest material requires careful research and local price comparisons. It’s essential to obtain quotes from multiple suppliers and contractors to accurately assess the costs associated with each option. Remember to factor in long-term costs such as maintenance and energy efficiency.

Further considerations must extend beyond the immediate acquisition cost of the building material. A comprehensive cost-benefit analysis should incorporate the projected lifespan of the structure, anticipated maintenance requirements, and the potential for energy savings. For instance, while earthbag construction might offer a lower initial outlay, the long-term costs associated with weatherproofing, pest control, and potential structural repairs could ultimately negate any upfront savings. Similarly, opting for reclaimed materials, though environmentally commendable, necessitates rigorous inspection and potentially extensive restoration, thereby increasing labor expenditure and potentially compromising structural integrity.

ADDRESSING PERMITTING AND CODE COMPLIANCE

The selection of a building material is inextricably linked to local building codes and permitting regulations. Novel or unconventional materials, while potentially cost-effective, may encounter significant hurdles in obtaining necessary approvals. Demonstrating compliance with structural, fire safety, and energy efficiency standards often requires extensive documentation, engineering certifications, and potentially costly modifications to the original design. Consequently, the perceived cost advantages of certain materials could be eroded by the added expenses associated with navigating the regulatory landscape.

IMPACT OF DESIGN ON MATERIAL COSTS

Architectural design plays a pivotal role in optimizing material usage and minimizing construction expenses. Simple, rectangular designs inherently require less material and labor than complex, multi-faceted structures. Moreover, strategic material selection can further reduce costs; for example, utilizing locally sourced lumber for framing and employing cost-effective cladding materials can significantly impact the overall budget. Furthermore, the judicious placement of windows and doors can minimize material waste and optimize natural lighting, thereby reducing energy consumption and associated long-term costs.

A thorough evaluation of the building site is also paramount. Soil conditions, topography, and exposure to the elements can all influence material selection and construction techniques. For instance, unstable soil may necessitate costly foundation work, while exposure to extreme weather conditions may require more durable and weather-resistant materials. Failing to account for these site-specific factors can lead to unforeseen expenses and potentially compromise the structural integrity of the building.

In summation, the determination of the most economical building material is a multifaceted undertaking that demands meticulous planning and a comprehensive understanding of the interplay between material costs, labor expenses, regulatory requirements, and long-term operational considerations. The prudent selection of a building material necessitates a holistic perspective, incorporating both immediate financial implications and the enduring performance characteristics of the chosen materials. A thorough due diligence process, involving consultations with experienced contractors, architects, and local building officials, is crucial for making an informed decision that aligns with budgetary constraints and ensures the long-term viability of the construction project. Therefore, to truly ascertain the cheapest material to build a house with, one must adopt a comprehensive and analytical approach.