Building a house is a significant undertaking, and understanding the financial aspects is crucial for a successful project. One of the most significant factors influencing the overall budget is the cost of materials. Determining the average material cost to build a house can be tricky, as it depends on various factors such as the size and style of the house, the quality of materials chosen, and geographic location. The average material cost to build a house can vary significantly. Therefore, careful planning and research are essential to estimate costs accurately.

Factors Influencing Material Costs

Several key factors affect the overall material costs when constructing a home. These factors can fluctuate depending on market conditions, design choices, and unforeseen circumstances.

House Size and Design

The size of the house directly impacts the quantity of materials needed. A larger home requires more lumber, concrete, roofing materials, and so on. The complexity of the design also plays a role. Intricate architectural features, custom finishes, and non-standard layouts often necessitate specialized materials and increased labor costs.

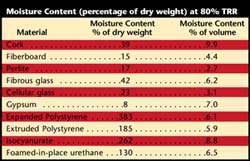

Material Quality and Selection

The quality of materials chosen has a significant impact on the budget. Opting for high-end finishes, premium lumber, and energy-efficient windows and doors will increase the cost but can also enhance the home’s value and longevity. Conversely, using more affordable materials can reduce upfront expenses but may require more frequent maintenance or replacement in the long run.

Geographic Location

Material costs can vary significantly depending on location. Areas with high demand, limited supply, or challenging transportation logistics tend to have higher prices. Additionally, local building codes and regulations may require specific materials, further influencing costs.

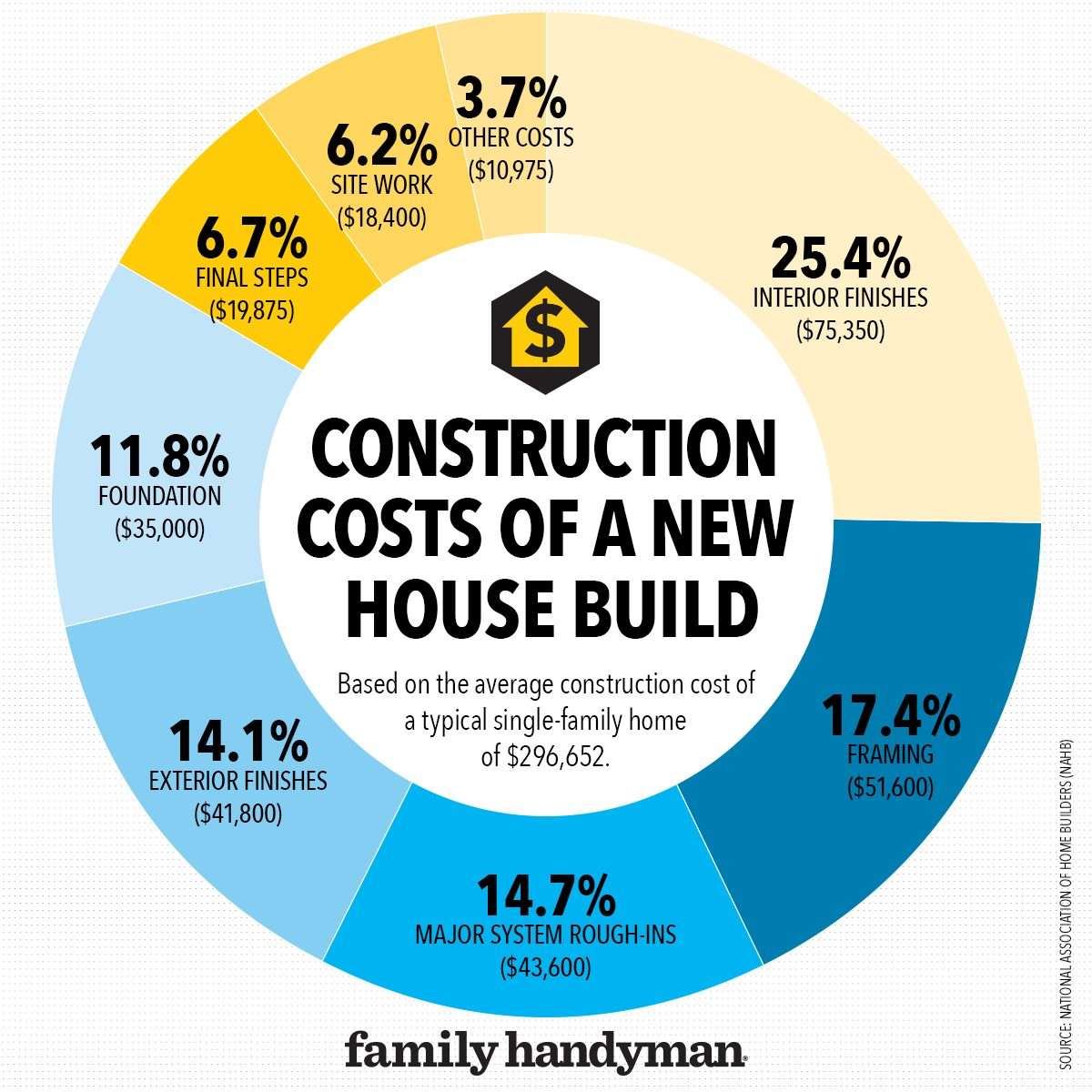

Estimating Material Costs: A General Overview

While precise figures are difficult to provide without specific project details, here’s a general overview of typical material costs as a percentage of the total construction budget:

- Lumber: 15-20%

- Concrete: 10-15%

- Roofing: 5-10%

- Windows & Doors: 10-15%

- Plumbing: 5-10%

- Electrical: 5-10%

- HVAC: 5-10%

- Insulation: 2-5%

- Finishes (Flooring, Cabinets, Countertops): 15-25%

These are just estimates, and actual percentages can vary widely. Getting detailed quotes from suppliers and contractors is essential for accurate budgeting.

Comparative Table: Material Cost Examples

| Material | Low-End Cost | Mid-Range Cost | High-End Cost |

|---|---|---|---|

| Flooring (per sq. ft.) | $2 | $5 | $15+ |

| Cabinets (per linear ft.) | $100 | $300 | $1000+ |

| Countertops (per sq. ft.) | $20 | $50 | $100+ |

These examples illustrate the wide range of costs associated with different material choices. Careful consideration should be given to balancing budget constraints with desired quality and aesthetics.

WHAT IS THE AVERAGE MATERIAL COST TO BUILD A HOUSE?

Building a house is a significant undertaking, and understanding the financial aspects is crucial for a successful project. One of the most significant factors influencing the overall budget is the cost of materials. Determining the average material cost to build a house can be tricky, as it depends on various factors such as the size and style of the house, the quality of materials chosen, and geographic location. The average material cost to build a house can vary significantly. Therefore, careful planning and research are essential to estimate costs accurately.

FACTORS INFLUENCING MATERIAL COSTS

Several key factors affect the overall material costs when constructing a home. These factors can fluctuate depending on market conditions, design choices, and unforeseen circumstances.

HOUSE SIZE AND DESIGN

The size of the house directly impacts the quantity of materials needed. A larger home requires more lumber, concrete, roofing materials, and so on. The complexity of the design also plays a role. Intricate architectural features, custom finishes, and non-standard layouts often necessitate specialized materials and increased labor costs.

MATERIAL QUALITY AND SELECTION

The quality of materials chosen has a significant impact on the budget. Opting for high-end finishes, premium lumber, and energy-efficient windows and doors will increase the cost but can also enhance the home’s value and longevity. Conversely, using more affordable materials can reduce upfront expenses but may require more frequent maintenance or replacement in the long run.

GEOGRAPHIC LOCATION

Material costs can vary significantly depending on location. Areas with high demand, limited supply, or challenging transportation logistics tend to have higher prices; Additionally, local building codes and regulations may require specific materials, further influencing costs.

ESTIMATING MATERIAL COSTS: A GENERAL OVERVIEW

While precise figures are difficult to provide without specific project details, here’s a general overview of typical material costs as a percentage of the total construction budget:

– Lumber: 15-20%

– Concrete: 10-15%

– Roofing: 5-10%

– Windows & Doors: 10-15%

– Plumbing: 5-10%

– Electrical: 5-10%

– HVAC: 5-10%

– Insulation: 2-5%

– Finishes (Flooring, Cabinets, Countertops): 15-25%

These are just estimates, and actual percentages can vary widely. Getting detailed quotes from suppliers and contractors is essential for accurate budgeting.

COMPARATIVE TABLE: MATERIAL COST EXAMPLES

Material

Low-End Cost

Mid-Range Cost

High-End Cost

Flooring (per sq. ft.)

$2

$5 $15+

Cabinets (per linear ft.)

$100

$300

$1000+

Countertops (per sq. ft.)

$20

$50 $100+

These examples illustrate the wide range of costs associated with different material choices. Careful consideration should be given to balancing budget constraints with desired quality and aesthetics.

In conclusion, understanding what is the average material cost to build a house is paramount for effective project management and financial planning. By carefully considering the factors influencing material costs, obtaining detailed quotes, and making informed decisions, homeowners can navigate the construction process with greater confidence and ensure a successful outcome.

TIPS FOR MANAGING MATERIAL COSTS

Beyond understanding the averages and influencing factors, proactive measures can significantly impact your overall material expenses. Here are some key tips to consider:

GET MULTIPLE QUOTES

Don’t settle for the first quote you receive. Obtain estimates from several suppliers and contractors for each material category. This allows you to compare prices and potentially negotiate better deals. Be sure to compare “apples to apples,” ensuring each quote includes the same quality and quantity of materials.

PLAN AHEAD AND ORDER EARLY

Avoid last-minute rushes and potential price increases by planning your material orders well in advance. Ordering materials early can also help you secure better pricing and avoid delays due to supply chain issues. This is especially crucial for custom or specialty items that may have longer lead times.

CONSIDER VALUE ENGINEERING

Value engineering involves analyzing the design and materials to identify potential cost savings without compromising quality or functionality. This might involve exploring alternative materials, simplifying design elements, or optimizing material usage. Consult with your architect and contractor to identify value engineering opportunities.

MONITOR MATERIAL USAGE AND WASTE

Construction sites can generate significant material waste. Implement measures to minimize waste by accurately calculating material needs, properly storing materials to prevent damage, and recycling or repurposing excess materials whenever possible. This not only saves money but also promotes environmentally responsible building practices.

BE FLEXIBLE AND OPEN TO ALTERNATIVES

Sometimes, unforeseen circumstances or market fluctuations can impact material availability or pricing. Be prepared to be flexible and consider alternative materials or design adjustments if necessary. Your contractor can help you identify suitable alternatives that meet your needs and budget.

By following these advisory tips, you can proactively manage your material costs, reduce potential expenses, and ensure that building a house remains a financially sound investment. Remember, informed decisions and careful planning are your best allies in navigating the complexities of home construction;