The world of interior design is constantly evolving, and the humble bathroom is no exception. While elaborate and opulent designs often dominate magazines, there’s a growing appreciation for the understated elegance and practicality of simple designs, particularly when it comes to Indian aesthetics. Exploring simple Indian bathroom tiles design photos can reveal a wealth of inspiration for creating a serene and functional space. This article delves into the nuances of simple Indian bathroom design, offering unique perspectives and ideas that go beyond the typical trends to give you the best simple Indian bathroom tiles design photos to choose from.

Embracing Minimalism: Less is More

In Indian design, the concept of “less is more” can be beautifully translated into a bathroom space. Instead of overwhelming the room with busy patterns and clashing colors, focus on clean lines, natural materials, and a calming color palette. This approach not only creates a sense of spaciousness but also promotes relaxation and tranquility.

- Color Palette: Opt for neutral tones like off-white, beige, light grey, or earthy browns. These colors create a soothing backdrop that complements a variety of tile designs.

- Tile Size: Larger tiles can make a small bathroom appear bigger. Consider using rectangular tiles laid horizontally to visually expand the space.

- Layout: Keep the layout simple and functional. Avoid clutter and maximize storage to maintain a clean and organized look.

Tile Materials and Textures: Adding Depth

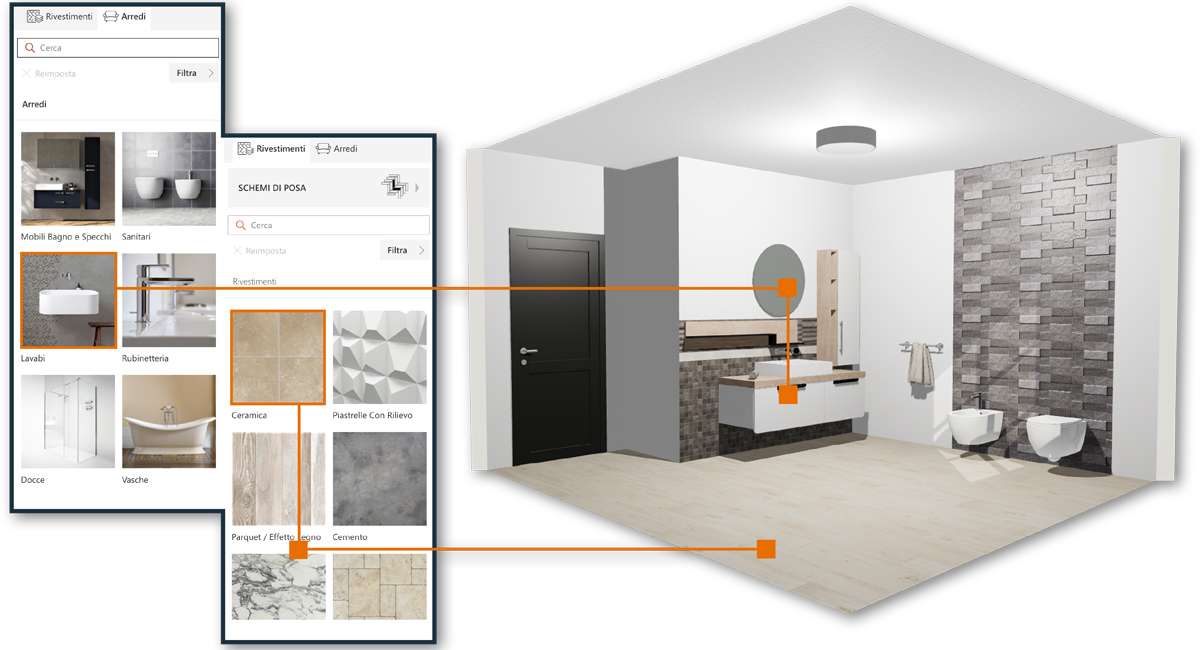

While the overall design is simple, you can still add visual interest through the choice of tile materials and textures. Incorporating natural stone or textured tiles can bring depth and character to the bathroom.

Popular Tile Choices:

- Ceramic Tiles: A cost-effective and versatile option available in a wide range of colors and patterns.

- Porcelain Tiles: More durable and water-resistant than ceramic, making them ideal for bathroom floors and walls.

- Natural Stone Tiles: Such as marble, granite, or slate, add a touch of luxury and natural beauty.

- Terracotta Tiles: Offer a rustic and earthy feel, perfect for creating a warm and inviting atmosphere.

Design Inspiration: Simple Yet Stunning

The beauty of simplicity lies in its versatility. You can adapt simple Indian bathroom design to suit your personal style and preferences. Here are a few ideas to get you started:

- Accent Walls: Use a different tile color or texture on one wall to create a focal point.

- Border Tiles: Add a decorative border around the perimeter of the bathroom or around the shower area.

- Geometric Patterns: Incorporate subtle geometric patterns to add visual interest without overwhelming the space.

Below is a comparative table showcasing how different tile materials can influence the overall aesthetic and functionality of a simple Indian bathroom design:

| Tile Material | Aesthetic | Durability | Water Resistance | Cost |

|---|---|---|---|---|

| Ceramic | Versatile, Available in many colors/patterns | Medium | Medium | Low to Medium |

| Porcelain | Modern, Clean | High | High | Medium |

| Natural Stone | Luxurious, Natural | High (depending on stone type) | Medium to High (depending on stone type) | High |

| Terracotta | Rustic, Earthy | Medium | Low (requires sealing) | Medium |

Beyond tiles, consider the impact of other bathroom fixtures. A simple, clean-lined vanity made of wood or a light-colored laminate can complement the tile design without overpowering the space. Opt for a minimalist faucet and showerhead in brushed nickel or chrome to maintain a cohesive look. Mirrors are also crucial elements; a large, frameless mirror can create the illusion of more space and reflect light throughout the room. Avoid ornate or overly decorative accessories, as they can detract from the overall simplicity of the design.

LIGHTING: ILLUMINATING SIMPLICITY

Proper lighting is essential for creating a functional and inviting bathroom. In a simple Indian bathroom design, focus on natural light whenever possible. If natural light is limited, incorporate a combination of ambient, task, and accent lighting to create a well-lit and balanced space.

– Ambient Lighting: Provides overall illumination for the room. Recessed lighting or a simple ceiling fixture are good options.

– Task Lighting: Focuses on specific areas, such as the vanity or shower. Consider installing vanity lights or a shower light.

– Accent Lighting: Highlights specific features, such as artwork or decorative tiles. Use spotlights or strip lighting to create visual interest.

ADDING A PERSONAL TOUCH: SUBTLE ACCENTS

While the overall design should be simple, you can still add personal touches to make the bathroom your own. Incorporate elements that reflect your personality and style, such as plants, artwork, or decorative accessories.

– Plants: Add a touch of greenery and freshness to the bathroom. Choose plants that thrive in humid environments, such as ferns or orchids.

– Artwork: Hang a simple painting or print to add visual interest. Opt for artwork that complements the color palette and overall design.

– Textiles: Choose soft and absorbent towels in neutral colors. Add a simple rug or bath mat for comfort and warmth.

Remember to prioritize functionality and practicality when choosing accessories. Avoid clutter and keep the space clean and organized. A well-designed simple Indian bathroom can be a haven of tranquility and relaxation, providing a refreshing start to your day and a peaceful retreat in the evening.