Embarking on the journey of constructing a 10×12 shed is a rewarding project that adds valuable storage space and enhances your property. Before you start hammering and sawing, a crucial step is gathering the necessary materials. Planning is paramount, and understanding the specific materials needed is the first building block in ensuring the project is a success. This comprehensive guide will outline everything you need to bring your 10×12 shed vision to life, covering everything from the foundation to the roofing and siding.

Foundation Materials

Your shed’s foundation is the bedrock upon which the entire structure rests. Choosing the right materials and construction method is crucial for longevity and stability. Here are a few common foundation options:

- Concrete Slab: Requires concrete mix, gravel base, rebar reinforcement, and form boards.

- Gravel Pad: Consists of compacted gravel (typically crushed stone or pea gravel) and landscape fabric to prevent weed growth.

- Wooden Skid Foundation: Utilizes pressure-treated lumber for the skids, gravel for leveling, and potentially concrete blocks for added support.

Framing Materials

The frame provides the structural skeleton of your shed. Selecting high-quality lumber is essential for a sturdy and durable building.

- Lumber: Primarily pressure-treated lumber (typically 2x4s for wall studs and 2x6s or 2x8s for rafters) is needed. The exact quantity will depend on your design and spacing.

- Fasteners: This includes nails (various sizes), screws, and potentially construction adhesive for added strength. Consider using galvanized or exterior-rated fasteners to resist corrosion.

- Sheathing: Plywood or OSB (Oriented Strand Board) is used to cover the frame and provide a solid surface for siding.

Roofing Materials

The roof protects your shed from the elements. Consider these options:

- Asphalt Shingles: A popular and affordable choice. Requires underlayment (roofing felt), shingles, and roofing nails.

- Metal Roofing: Durable and long-lasting but can be more expensive. Requires metal panels, screws, and flashing.

- Wood Shingles/Shakes: Offers a rustic look but requires regular maintenance.

Siding Materials

Siding protects the walls and gives your shed its aesthetic appeal.

- Wood Siding: Options include clapboard, board and batten, and shiplap. Requires nails or screws and paint or stain.

- Vinyl Siding: Low-maintenance and comes in various colors and styles. Requires nails or screws and trim pieces.

- Engineered Wood Siding (e.g., LP SmartSide): Durable and resistant to rot and insects. Requires nails or screws and paint or stain.

Door and Window Materials

These elements provide access and ventilation.

- Door: Pre-hung doors are easiest to install. Consider the size and style of your door.

- Windows: Choose windows based on your desired light and ventilation.

- Hardware: Hinges, latches, handles, and locks are essential for doors and windows.

Other Essential Materials

- Concrete Mix: For setting posts, building the slab, or making footings.

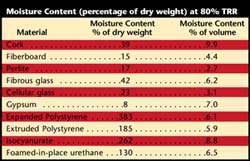

- Insulation: Optional, but helpful for temperature control and condensation prevention.

- Paint or Stain: To protect and beautify the siding and trim.

- Caulk and Sealant: To seal gaps and prevent water intrusion.

- Gutters and Downspouts: To direct rainwater away from the shed.

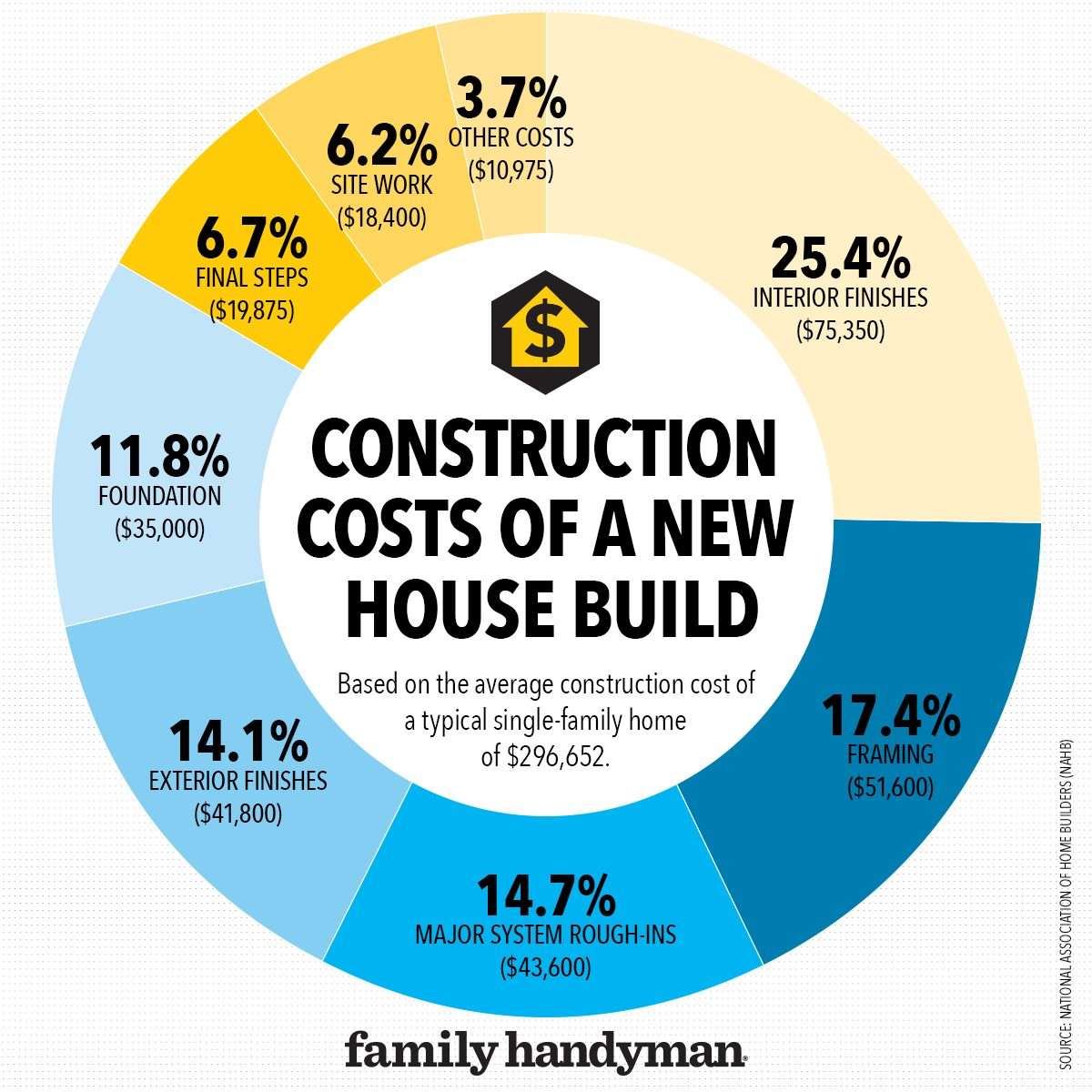

Estimating Quantities and Costs

The quantity of each material will depend on your specific 10×12 shed design and the chosen foundation, roofing, and siding options. It’s highly recommended to create a detailed materials list based on your plans and then get quotes from multiple suppliers to compare prices. Don’t forget to factor in delivery charges and potential waste when estimating quantities.

Final Thoughts on Building your 10×12 Shed

Careful planning and material selection are key to building a successful and long-lasting 10×12 shed. By taking the time to research your options and choose the right materials, you can create a functional and attractive storage solution for your property. Remember to consult local building codes and obtain any necessary permits before starting your project. Enjoy the process of creating something useful with your own hands!

TOOLS AND EQUIPMENT

Beyond the raw materials, a comprehensive toolkit is indispensable for the efficacious execution of this construction endeavor. The selection of appropriate tools not only streamlines the building process but also contributes significantly to the overall quality and precision of the finished structure. The following list delineates essential tools and equipment, categorized for clarity and ease of reference:

– Measuring and Marking: Tape measure (minimum 25 feet), level (at least 4 feet), square, chalk line, pencil, and marker. These instruments are fundamental for ensuring accurate dimensions, plumb lines, and square angles, which are paramount for structural integrity.

– Cutting: Circular saw, reciprocating saw (Sawzall), handsaw, and utility knife. The circular saw is the workhorse for cutting lumber and sheathing, while the reciprocating saw excels at demolition and cutting through difficult materials. A handsaw is useful for finer cuts and areas inaccessible to power tools.

– Fastening: Hammer, drill/driver with various bits, nail gun (optional but highly recommended), and screw gun (optional). A hammer is essential for driving nails, while a drill/driver is indispensable for pre-drilling holes and driving screws. A nail gun expedites the framing process significantly, and a screw gun provides greater control and precision when driving screws.

– Safety: Safety glasses, work gloves, hearing protection, and dust mask. Adherence to safety protocols is non-negotiable. Safety glasses protect against flying debris, work gloves prevent hand injuries, hearing protection mitigates noise exposure, and a dust mask safeguards against respiratory hazards.

– Other: Ladder, wheelbarrow, shovel, post hole digger (if using posts), and work table. A ladder provides access to elevated areas, a wheelbarrow facilitates the transport of materials, a shovel is necessary for excavation, a post hole digger is required for setting posts, and a work table provides a stable surface for cutting and assembling materials.

PERMITTING AND REGULATORY COMPLIANCE

Prior to the commencement of any construction activity, it is imperative to ascertain the specific permitting requirements mandated by the relevant local authorities. Building codes and zoning regulations vary considerably from jurisdiction to jurisdiction, and non-compliance can result in substantial fines, project delays, or even the complete cessation of construction. The following steps are recommended to ensure regulatory compliance:

– Contact Local Building Department: Initiate contact with the local building department to inquire about the specific permitting requirements for a 10×12 shed. Obtain all necessary application forms and informational brochures.

– Submit Plans and Drawings: Prepare detailed plans and drawings of the proposed shed, including dimensions, materials specifications, and site plan. Submit these documents to the building department for review and approval.

– Schedule Inspections: Be prepared to schedule inspections at various stages of the construction process, such as foundation, framing, and final inspection. Ensure that all work complies with the approved plans and building codes.

– Obtain Final Approval: Upon successful completion of all inspections, obtain final approval from the building department. This documentation serves as proof of compliance with all applicable regulations.

WASTE MANAGEMENT AND ENVIRONMENTAL CONSIDERATIONS

Responsible waste management and adherence to environmental best practices are paramount during the construction process. Proper disposal of construction debris not only minimizes environmental impact but also contributes to a safer and more organized worksite. The following guidelines should be observed:

– Recycle Materials: Whenever feasible, recycle construction materials such as lumber, metal, and cardboard. Contact local recycling centers for information on acceptable materials and drop-off locations.

– Dispose of Waste Properly: Dispose of non-recyclable waste in designated containers. Avoid burning construction debris, as this can release harmful pollutants into the atmosphere.

– Prevent Soil Erosion: Implement measures to prevent soil erosion, such as using silt fences or hay bales to contain sediment runoff.

– Protect Water Resources: Avoid contaminating water resources with construction materials or chemicals. Properly dispose of any hazardous waste, such as paint or solvents.

The successful culmination of a 10×12 shed construction project hinges not only on the acquisition of appropriate materials and tools but also on meticulous planning, diligent execution, and unwavering adherence to regulatory and environmental guidelines. This holistic approach ensures the creation of a durable, functional, and aesthetically pleasing structure that enhances the value and utility of the property. Remember, meticulous attention to detail throughout the entire process, from initial planning to final inspection, will ultimately determine the long-term success and satisfaction derived from your newly constructed 10×12 shed.