The allure of Orlando extends beyond theme parks and sunshine; it’s a thriving community constantly evolving. As such, construction and renovation projects are commonplace, leading to a unique opportunity for savvy individuals to acquire **used building materials for sale by owner Orlando**. Opting for these materials is not only a financially prudent decision but also contributes significantly to environmental sustainability by diverting perfectly usable items from landfills. The market for **used building materials for sale by owner Orlando** offers a diverse range of options, from lumber and bricks to fixtures and appliances, waiting to be repurposed and given a new lease on life. By embracing this alternative, homeowners and contractors alike can reduce project costs, minimize their environmental footprint, and potentially uncover unique and character-rich elements for their projects.

Why Choose Used Building Materials?

There are numerous compelling reasons to explore the market for used building materials. Beyond the obvious cost savings, consider the following:

- Environmental Responsibility: Reduces waste and lowers the demand for new resources.

- Unique Character: Adds a touch of history and individuality to your project.

- Cost Savings: Significantly lower prices compared to new materials.

- Supporting Local Economy: Often involves transactions within your community.

Finding the Right Materials in Orlando

Navigating the market for used building materials requires a strategic approach. Online marketplaces, local classifieds, and community bulletin boards are excellent starting points. Consider these tips for a successful search:

- Be Specific: Clearly define your needs and search terms (e.g., “used lumber Orlando”, “used doors Orlando”).

- Inspect Thoroughly: Always examine materials in person before purchasing to assess condition and suitability.

- Negotiate Prices: Don’t be afraid to haggle; many sellers are open to negotiation.

- Verify Legality: Ensure the seller has the right to sell the materials to avoid any legal issues.

Potential Challenges and Solutions

While the benefits are significant, purchasing used building materials can present challenges:

- Availability: Finding the exact quantity and type of material you need may require patience. Solution: Plan ahead and be flexible with your project design.

- Condition: Materials may have imperfections or require cleaning/repair. Solution: Thoroughly inspect before purchase and factor in potential restoration costs.

- Transportation: You may need to arrange transportation for bulky items. Solution: Consider renting a truck or hiring a moving service.

A Sustainable Future for Orlando Construction

The market for used building materials is poised for continued growth as awareness of environmental sustainability increases. By embracing this practice, Orlando can move towards a more circular economy, where resources are reused and recycled, minimizing waste and maximizing value. The final paragraph reminds you that finding **used building materials for sale by owner Orlando** is a powerful way to contribute to a more sustainable future for our city, both economically and environmentally.

LEGAL CONSIDERATIONS AND DUE DILIGENCE

Prior to finalizing any transaction involving used building materials, it is imperative to conduct thorough due diligence. While many sales are straightforward, certain circumstances may warrant further investigation to ensure compliance with local ordinances and regulations. Specifically, ascertain the provenance of the materials to mitigate the risk of acquiring stolen goods or items subject to liens. Request documentation demonstrating ownership or legal authorization for the sale. Furthermore, confirm that the materials meet applicable building codes and safety standards, particularly if they are intended for structural applications. Engage with local permitting authorities if uncertainty exists regarding the suitability of the materials for your intended use; Failure to adhere to these precautionary measures may result in project delays, financial penalties, or even legal ramifications.

CONTRACTUAL AGREEMENTS AND PAYMENT TERMS

To safeguard both the buyer and seller, a written contract outlining the terms of the agreement is highly recommended. This contract should explicitly detail the following:

– Itemized List of Materials: A comprehensive inventory of all items included in the sale, specifying quantities, dimensions, and any relevant identifying characteristics.

– Purchase Price and Payment Schedule: The agreed-upon price for the materials and the schedule for payment, including any deposits or installments.

– Delivery or Pickup Arrangements: Clear stipulations regarding the transportation of the materials, including responsibility for loading, unloading, and any associated costs.

– Warranty or Disclaimer: A statement outlining whether the seller provides any warranty regarding the condition or suitability of the materials, or a clear disclaimer indicating that the materials are sold “as is.”

– Dispute Resolution Mechanism: A clause outlining the process for resolving any disputes that may arise between the buyer and seller.

Regarding payment terms, consider utilizing secure payment methods that offer buyer protection, such as escrow services or credit cards. Avoid making large cash payments without proper documentation and verification of the seller’s identity.

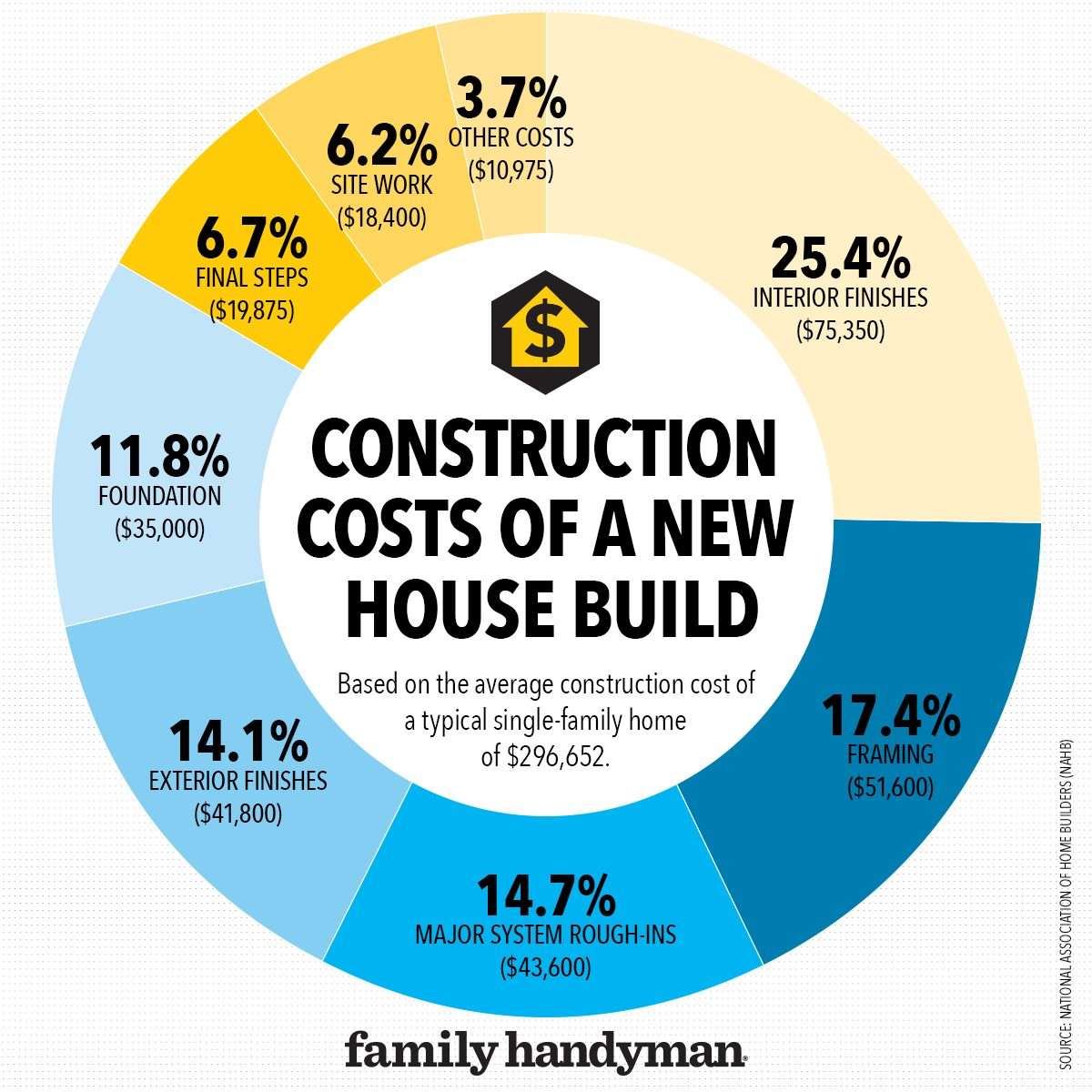

COMPARATIVE ANALYSIS: NEW VS. USED BUILDING MATERIALS

The decision to utilize new versus used building materials necessitates a careful assessment of various factors. The following table provides a comparative analysis to aid in this decision-making process:

Factor

New Building Materials

Used Building Materials

Cost

Generally higher initial cost.

Significantly lower initial cost.

Availability

Readily available in standard sizes and quantities.

Availability may be limited and require more extensive searching.

Condition

Typically in pristine condition.

May require cleaning, repair, or restoration.

Warranty

Often covered by manufacturer warranties.

Typically sold “as is” without warranty.

Environmental Impact

Higher environmental impact due to resource extraction and manufacturing.

Lower environmental impact due to reuse and waste reduction.

Aesthetics

Consistent and uniform appearance.

May possess unique character and historical significance.

Ultimately, the optimal choice depends on the specific requirements of the project, budgetary constraints, and the level of acceptable risk. A thorough evaluation of these factors will ensure an informed and successful decision.